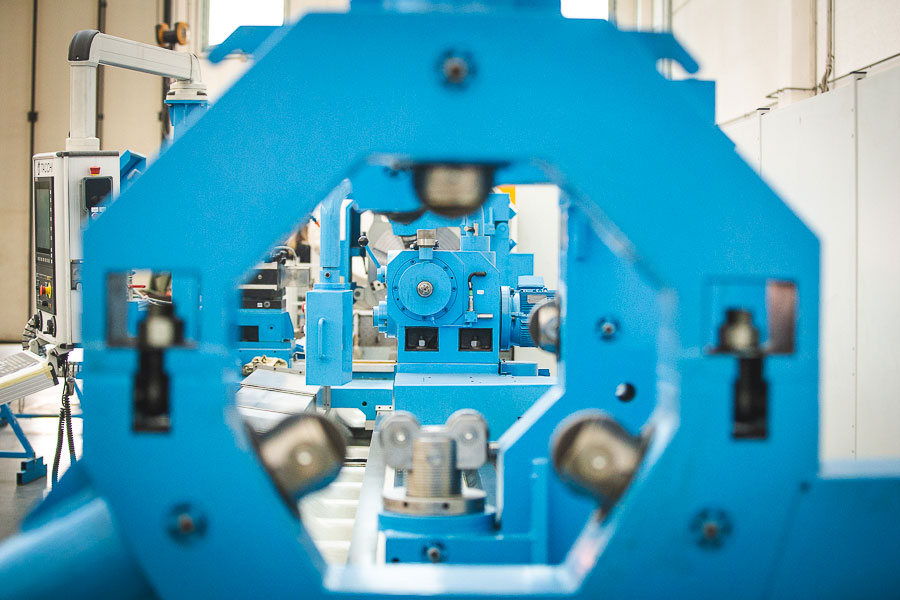

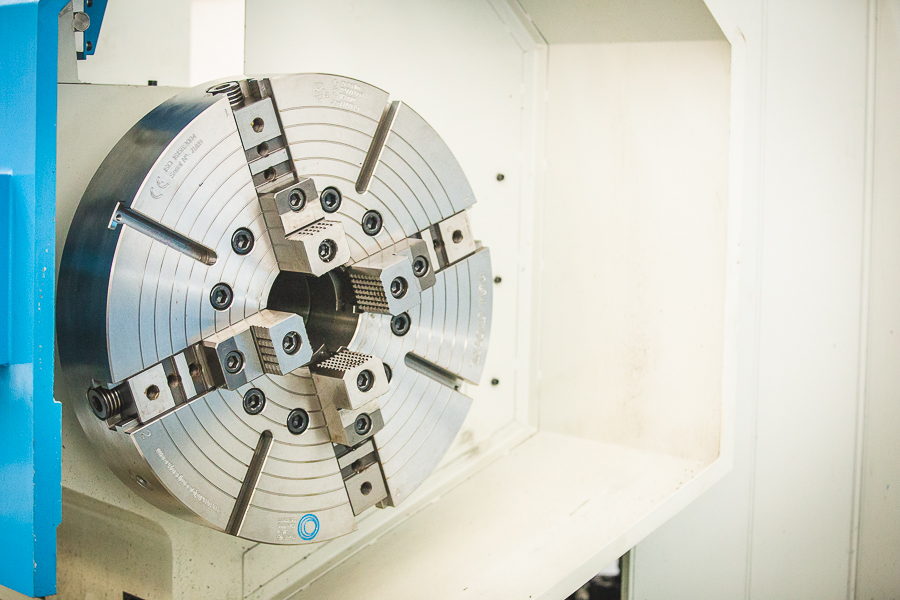

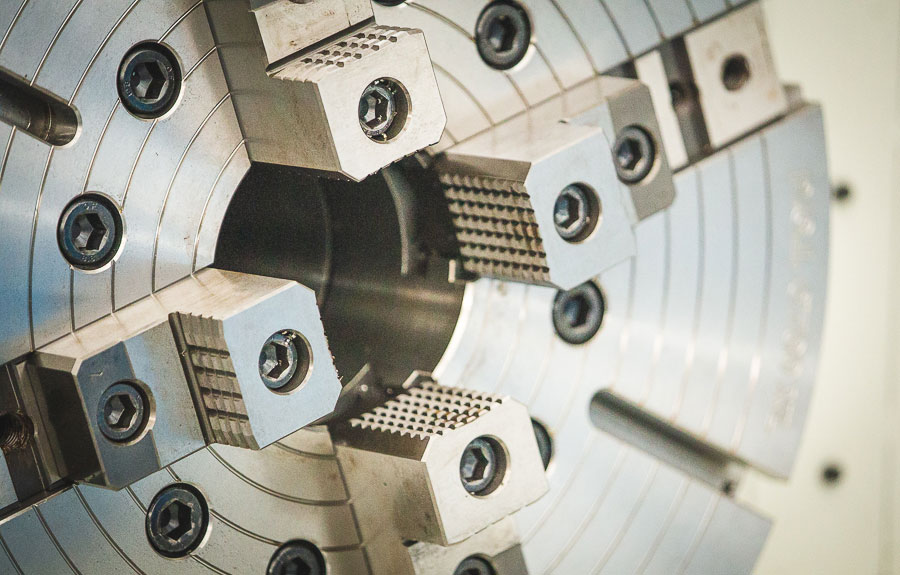

Turning industrial shafts up to 10 meters in length is one of our specialties. Thanks to our advanced CNC technology, we can machine large components with tight tolerances and perfect surface finishes. The materials we work with include steel, special alloys, and other metals, ideal for applications in the naval, energy, and industrial sectors.

Precision Turning Services for Industrial Components

Turning of Industrial Shafts up to 10 Meters

Precision and Reliability for Large Shafts

Turning of Small, Medium, and Large Dimensions - Application Sectors

Our turning services for industrial shafts are used in various sectors, including:

- Naval: Engine shafts and transmission shafts for ships and vessels.

- Industrial: Shafts for heavy machinery and production plants.

Large-Scale Turning for Industrial Components

Unique Capabilities in the Industry

Se.r.navi stands out for its ability to machine large components, up to 10 meters in length and 8 tons in weight. Our CNC machinery is designed to ensure precision and reliability, even on exceptionally large parts.

Advantages of Large-Scale Turning

- Millimetric Precision: We guarantee tight tolerances and high-quality surface finishes.

- Flexibility: We can work with a wide range of materials, including steel, special alloys, and cast iron.

- Years of Experience: Our team boasts decades of expertise in large-scale turning.

Propeller Shaft Line Construction in the Naval Sector

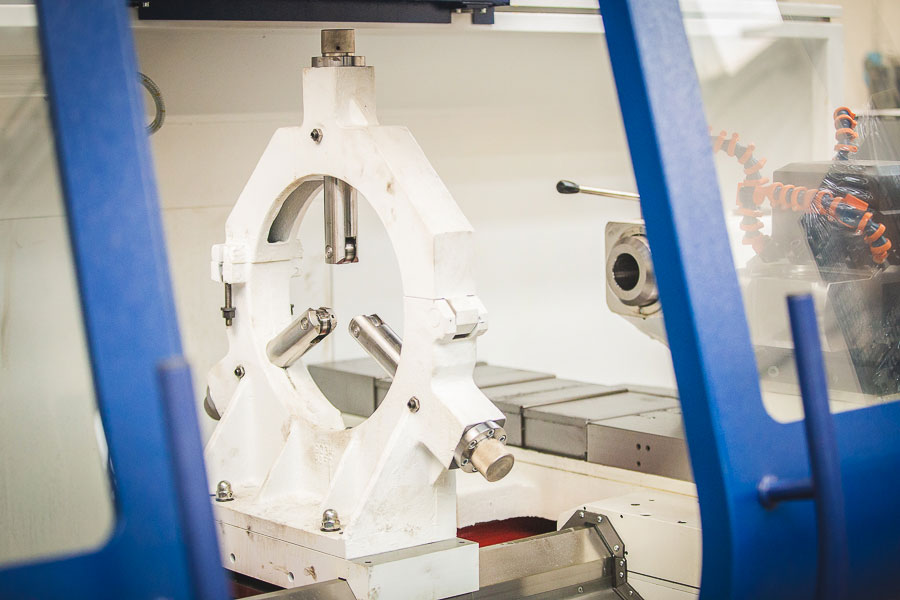

Propeller shaft lines are a fundamental element in naval propulsion, connecting the engine to the propeller and ensuring the transmission of the necessary power for navigation. Se.r.navi, thanks to its experience and advanced technologies, manufactures custom shaft lines with the highest precision, ensuring efficiency, reliability, and long service life.

What Are Propeller Shaft Lines and Their Importance?

Propeller shaft lines are essential mechanical components that transmit rotational motion from the reducer to the propeller, allowing the vessel to move. They must be precisely designed to minimize vibrations, friction, and energy loss, ensuring high propulsion efficiency. The choice of materials, balancing, and proper assembly are critical factors in achieving optimal performance.

Se.r.navi's Advanced Technologies for Shaft Line Construction

Se.r.navi utilizes state-of-the-art machinery for shaft line construction, ensuring high-precision machining. Available technologies include:

- Precision turning up to 10 meters. Grinding and dynamic balancing to reduce vibrations and wear.

- Quality control with advanced instruments to guarantee minimal tolerances.

Thanks to these tools, Se.r.navi can produce perfectly aligned shaft lines that meet the requirements of the most sophisticated vessels.

Reliability and Customization

Every ship has specific needs, and Se.r.navi offers fully customized solutions for shaft line construction. Combining experience and innovation, the company can:

- Build shaft lines in various materials (steel, special alloys, bronze).

- Perform tests and simulations to verify component reliability.

- Provide assistance and maintenance to ensure maximum durability.

Se.r.navi’s ability to manufacture custom shaft lines with exceptional precision and durability makes it a benchmark in the naval industry.

turning of Industrial and Paper Industry Rolls

Customized Solutions for Industrial Rolls

The turning of industrial rolls requires specialized expertise and precision machinery. Se.r.navi offers comprehensive services, from turning to grinding and balancing, ensuring maximum durability and optimal performance for your rolls

Focus on the Paper Industry

In the paper industry, precision in roll machining is essential to ensure the proper functioning of machines. Our services include:

- Roll turning: Precision machining for large rolls.

- Grinding and balancing: Ensuring perfect flatness and balance of the rolls.

- Surface finishes: Specific treatments to enhance wear and corrosion resistance.

Turnable Industrial Components up to 10 Meters: Complete List of Large-Scale Machinable Parts

Here is a list of industrial components that can be turned with lathes capable of handling up to 10 meters in length:

- Transmission shafts: Used in industrial machinery to transmit power.

- Hydraulic and pneumatic cylinders: Essential components for handling and lifting systems.

- Rolling mill rolls: Used in the steel industry for sheet and profile production.

- Engine shafts: Critical components for engines and turbines.

- Wind turbine components: Including main shafts and supports.

- Large bearings: Used in heavy machinery and industrial plants.

- Marine and vessel components: Such as propulsion shafts, engine components, and supports.

- Die-casting molds: Used for manufacturing metal components.

- Power plant components: Such as generator and turbine shafts.

- Large pipes and conduits: For the oil and chemical industries.

- Agricultural machinery components: Such as transmission shafts and rolls.

- Supports and bases for heavy machinery: Used in various industrial sectors.

- Wood processing plant components: Including shafts and rolls.

- Textile machinery components: Including cylinders and transmission shafts.

These are just a few examples, but our turning capacity of up to 10 meters in length allows us to work on a wide range of large industrial components.

Turning of Hydraulic Cylinders: Precision and Reliability for Every Application

The turning of hydraulic cylinders is a fundamental process to ensure the proper functioning of industrial plants, heavy machinery, and hydraulic systems. Thanks to advanced technologies and high-precision machining, Se.r.navi offers customized solutions for the manufacturing and regeneration of hydraulic cylinders, ensuring quality, durability, and high performance.

Custom Hydraulic Cylinder Turning Services

Our hydraulic cylinders are used in various applications, including:

- Industrial machinery: Cylinders for hydraulic presses and heavy machinery.

- Automotive sector: Components for hydraulic vehicle systems.

- Agriculture: Cylinders for agricultural machines and equipment.

- Precision turning of medium and large cylinders for various industrial sectors.

- Restoration and regeneration of worn cylinders, extending component lifespan.

- High-performance materials processed with cutting-edge machinery.

- Strict quality controls to ensure maximum efficiency and safety of hydraulic cylinders.

Cutting-Edge Technology

Why Choose Se.r.navi for Turning Services?

We use state-of-the-art CNC machines capable of guaranteeing millimetric precision and perfect surface finishes. Our fleet of machines is constantly updated to offer the best performance.

Experience and Expertise

With over 50 years of experience in industrial turning, Se.r.navi boasts a team of experts capable of handling any challenge, from machining large shafts to turning rolls for the paper industry.

Se.r.navi’s workshop is equipped with the following lathes:

- Auto-Learning Lathe 300×6000

- CNC Lathe 525×10000

- Manual Parallel Lathe, quick single-pulley, center distance 2000mm

- Manual Parallel Lathe, Single Pulley

- Manual Parallel Lathe 700×4000

Thanks to 10T overhead cranes, Se.r.navi can handle large materials.

Customized Services

We offer tailored solutions for every need, from design to final machining. Our goal is to ensure maximum customer satisfaction, with fast delivery times and unparalleled attention to detail.

Contact Us for a Custom Quote

If you need precision turning services for shafts, rolls, or hydraulic cylinders, Se.r.navi is the ideal partner. Contact us today for a personalized quote and find out how we can help you achieve your goals.

FAQ on Industrial Turning

What materials can you work with?

We work with a wide range of materials, including steel, special alloys, cast iron, bronze, aluminum, and more. Each material requires a specific approach, ensured by our experience and advanced technology.

What are the delivery times?

Delivery times vary based on the complexity of the project. However, we are committed to meeting agreed deadlines without compromising work quality.

Do you offer surface finishing services?

Yes, in addition to turning, we offer surface finishing services, including grinding, balancing, and wear-resistant treatments.