In the industrial sector, precision mechanical machining of medium and large components is essential to ensure the efficiency and quality of final products. Ser.Navi, based in Marghera (VE), boasts over 50 years of experience in this field, offering specialized services that meet the needs of both national and international clients.

Precision Mechanical Machining for Medium and Large Components with Ser.Navi

Services Offered by Ser.Navi

Ser.Navi’s mechanical workshop is equipped to perform a wide range of mechanical machining operations, including:

-

Milling: A process that shapes materials by chip removal, ideal for creating flat or contoured surfaces.

-

Boring: A technique used to enlarge or refine existing holes, ensuring dimensional accuracy and optimal surface finish.

-

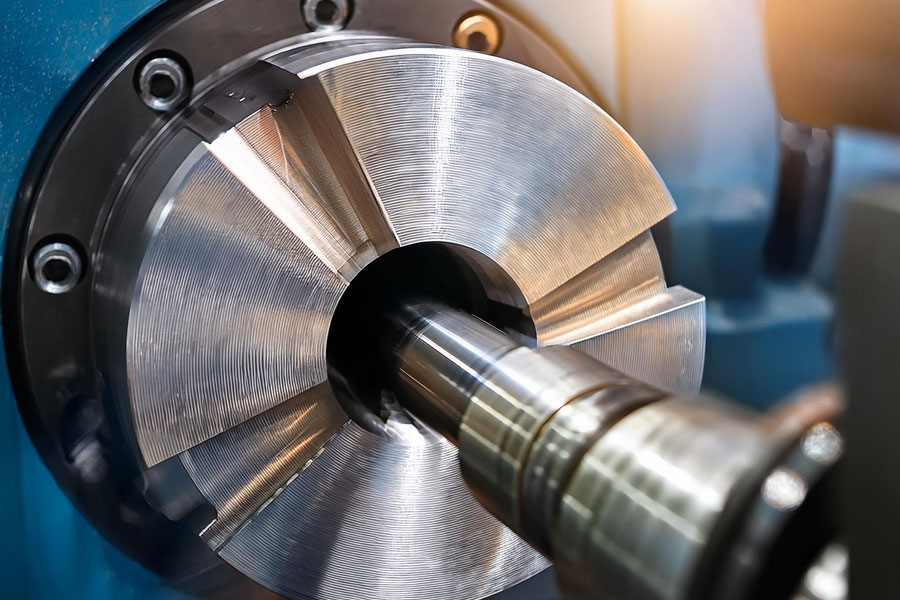

Turning: A machining process that creates cylindrical or conical surfaces by rotating the workpiece against a cutting tool.

-

Mechanical Fabrication: Manufacturing and assembling complex metal structures, essential for various industrial applications.

Operational Capabilities

Thanks to a cutting-edge machine park and highly specialized technicians, Ser.Navi can handle machining of components up to 10 meters in length. This flexibility allows the company to take on complex projects while maintaining high standards of precision and efficiency.

Application Sectors

Ser.Navi’s expertise is applicable across various industrial sectors, including:

-

Naval Industry: Maintenance and repair of essential components for vessels of various sizes.

-

Energy Sector: Production and overhaul of parts for power generation and distribution systems.

-

Manufacturing Industry: Production of machinery and equipment for production lines.

-

Petrochemical Sector: Construction and maintenance of components for refining and processing plants.

Hydraulic Cylinder Manufacturing

Manufacturing Process: Turning, Assembly, Welding, and Pressing

Ser.Navi specializes in the custom manufacturing of hydraulic cylinders, ensuring maximum precision and reliability through a complex and highly specialized production process. The process begins with turning operations to achieve the required dimensions and tolerances. The next step is the assembly of components, which is crucial for ensuring the proper function of the cylinder.

The welding phase is carried out by skilled technicians using advanced technologies to ensure long-lasting strength and durability. Finally, pressing ensures all elements are perfectly integrated and ready for use in demanding industrial environments.

Hydraulic Cylinder Repair

In addition to manufacturing, Ser.Navi offers hydraulic cylinder repair services, ideal for restoring the performance of worn or damaged components. With careful preliminary analysis and the use of state-of-the-art technology, each repair is performed with precision, fully recovering functionality and extending the service life of the cylinder. This service perfectly complements Ser.Navi’s overall offering for both industrial and naval sectors.

Overhaul and Repair of Critical Components

One of Ser.Navi’s core strengths is its ability to perform overhaul and repair of critical mechanical components such as:

-

Gear Reducers: Devices that reduce rotational speed while increasing torque—vital for many industrial applications.

-

Centrifugal Pumps: Used for fluid transport, their efficiency is key to proper plant operation.

-

Gears and Shafts: Key components in the transmission of power and movement within machinery.

-

Diesel Engines: Overhaul of medium-power diesel engines.

-

Screw Pumps and Water Treatment Plants: Repair, maintenance, and overhaul of wastewater treatment systems both on-site and in the workshop.

Heat Exchanger Construction and Retubing for Industrial Use

Heat exchangers play a crucial role in industrial thermal processes, ensuring efficiency and reliability. Ser.Navi offers specialized services in the construction and retubing of heat exchangers, providing customized solutions tailored to the specific needs of each plant.

The construction process involves the use of high-quality materials and advanced manufacturing techniques, ensuring equipment that is both durable and corrosion-resistant. Retubing is essential to restore the performance of existing exchangers by replacing worn or damaged tubes, thereby extending operational life and reducing unplanned downtime.

Choosing Ser.Navi means relying on a partner with solid industry experience, capable of delivering tailored, high-quality solutions that ensure plant efficiency and continuity.

Machining of Hydraulic Turbine Blades

Ser.Navi provides highly specialized services for the machining of hydraulic turbine blades, ensuring precision, reliability, and long-lasting performance. With extensive experience and advanced machinery, the company performs milling, turning, and grinding operations on components of various sizes and materials. Each process is optimized to enhance turbine performance, energy efficiency, and wear resistance. All machining is carried out to strict quality standards, delivering customized solutions for the hydroelectric and industrial sectors.

Advanced Technologies and Qualified Personnel

To ensure high-quality mechanical machining, Ser.Navi continually invests in advanced technologies and staff training. The company operates with the latest generation CNC machines that guarantee precision and repeatability. Specialized technicians regularly attend training courses to stay updated with industry developments.

Third-Party Metal Fabrication Services

Ser.Navi also offers third-party metal fabrication services, leveraging its expertise to meet specific customer needs. With a highly skilled team and cutting-edge equipment, the company manufactures custom metal components and structures, maintaining high-quality standards and short delivery times. This flexible approach allows Ser.Navi to adapt to different market demands with tailor-made solutions based on clients’ technical specifications.

Mechanical Carpentry

In the field of mechanical carpentry, Ser.Navi stands out for its ability to manufacture complex metal structures and components for various industrial sectors. The company handles the design, fabrication, and assembly of mechanical elements with precision and reliability at every stage of production. Its deep knowledge of materials and machining techniques enables Ser.Navi to tackle even the most challenging projects, delivering high-quality products tailored to customer needs.

Certifications and Quality Standards

Quality is a core value in Ser.Navi’s operational philosophy. The company implements rigorous controls throughout the entire production process, from design to final execution. This approach has allowed Ser.Navi to achieve internationally recognized certifications, attesting to the excellence of its services.

The Benefits of Partnering with Ser.Navi

Choosing Ser.Navi as a partner for medium and large-scale mechanical machining offers numerous advantages:

-

Years of Experience: Over half a century of operations built on expertise and reliability.

-

Tailored Solutions: Ability to adapt to specific customer needs with custom services.

-

Competitive Lead Times: Efficient organization ensures on-time delivery.

-

Comprehensive Support: Technical assistance and consulting throughout every project phase.

Completed Projects and Case Studies

Over the years, Ser.Navi has successfully completed numerous projects in collaboration with leading companies in their respective industries. These experiences highlight the company’s ability to tackle complex challenges and deliver effective, innovative solutions.

Contact and Information Request

For more details about the services offered by Ser.Navi or to request a personalized quote, please visit the Contact page or call +39 041 5381522.